Achieving both curing and transparency: LED UV adhesive technology for leaving no residue on hooks

In modern manufacturing, which pursues ultimate aesthetics and high-efficiency production, LEDUV (Light Emitting Diode Ultraviolet) curing adhesive, commonly known as UV adhesive, has become an ideal choice for precision bonding of products such as traceless hooks and transparent brackets due to its unique rapid curing and high transparency characteristics.

LEDUV adhesive is a one-component, solvent-free liquid adhesive that cures by exposure to ultraviolet light of a specific wavelength. The adhesive contains a special photoinitiator. When the LEDUV lamp emits a wavelength that matches the photoinitiator (typically 365nm or 395nm), the initiator absorbs the light energy. The activated initiator rapidly triggers free radical or cationic polymerization reactions in the resin and monomers of the adhesive, transforming the liquid adhesive into a strong, high-strength polymer solid layer within seconds.

Advantages of LEDUV Adhesive

For products requiring high precision and aesthetics, such as traceless hooks, LEDUV adhesive offers unparalleled advantages over traditional adhesives:

- High transparency (optical grade): The cured adhesive layer is almost 100% transparent, leaving no visible traces. This perfectly matches the aesthetic requirements of "traceless" hooks.

- Extremely fast curing speed: Curing time is typically within 1-10 seconds. This significantly improves the efficiency and capacity of automated production lines.

- Precise positioning: The adhesive remains liquid before curing, allowing for precise alignment of parts. This ensures accurate bonding between the hook body and the base.

- High bond strength: The cured adhesive layer has excellent tensile and shear strength. This guarantees reliable load-bearing capacity during use.

- Environmentally friendly: Contains no or very little VOCs (volatile organic compounds) and has no solvent emissions. This meets modern environmental standards for production.

The application of EDUV adhesive in the assembly of non-marking hooks is a highly automated process, crucial for precise control of adhesive dosage, positioning, and curing parameters.

Application Process

- Surface Pretreatment (Preparation)

- Cleansing: The hook body (typically PC or ABS plastic) and base plate (typically transparent PET or acrylic) need to be thoroughly cleaned to remove oil, dust, and mold release agents to ensure optimal bonding.

- Activation (Optional): For some difficult-to-bond plastic surfaces, plasma treatment or primer treatment may be necessary to increase surface energy.

- Precision Dispensing

- Automation: A precise amount of UV adhesive is applied to the designated bonding area of the hook body or base plate using high-precision dispensing equipment (such as a micro-dispensing machine).

- Adhesive Dosage Control: The amount of adhesive used must be precise; too much will overflow and affect aesthetics, while too little will affect bond strength.

- Parts Alignment and Pressing

- Precise Alignment: The hook body and base plate are precisely aligned and assembled using a robotic arm or tooling fixture.

- Air Bubble Removal: Gently press and squeeze out air between the bonding surfaces to ensure a uniform adhesive layer.

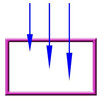

- LEDUV Curing (Core Step)

- Light Source Selection: Select an LEDUV curing machine (e.g., 365nm or 395nm) that matches the wavelength of the photoinitiator of the UV adhesive used.

- Irradiation: Place the aligned hook into the LEDUV curing area. The light source must be able to fully irradiate the adhesive layer, especially from the side or in shading conditions.

- Parameter Settings: Curing time and light intensity (usually measured in mW/cm²) must be strictly set according to the adhesive type and the material of the parts to ensure complete curing.

Key Considerations

Adhesive Selection: A UV adhesive specifically designed for plastic/metal bonding, with high transparency, low shrinkage, and wavelength matching the LED UV light, must be selected.

Shading Effect: When bonding opaque components, ensure that UV light can penetrate the transparent substrate or side path to reach the entire adhesive layer, avoiding "shadow areas" (i.e., uncured areas).

UV Intensity and Distance: The intensity of the curing lamp decreases rapidly with increasing distance. The distance between the lamp and the workpiece must be precisely set, and the light intensity meter must be calibrated regularly.

In conclusion, LED UV curing technology, with its efficient, clean, and high-quality bonding characteristics, is becoming an indispensable key process in the manufacture of precision household products such as traceless hooks.